- Te Huur

- Te Koop

- Ons Assortiment

- Gebruikt Materiaal

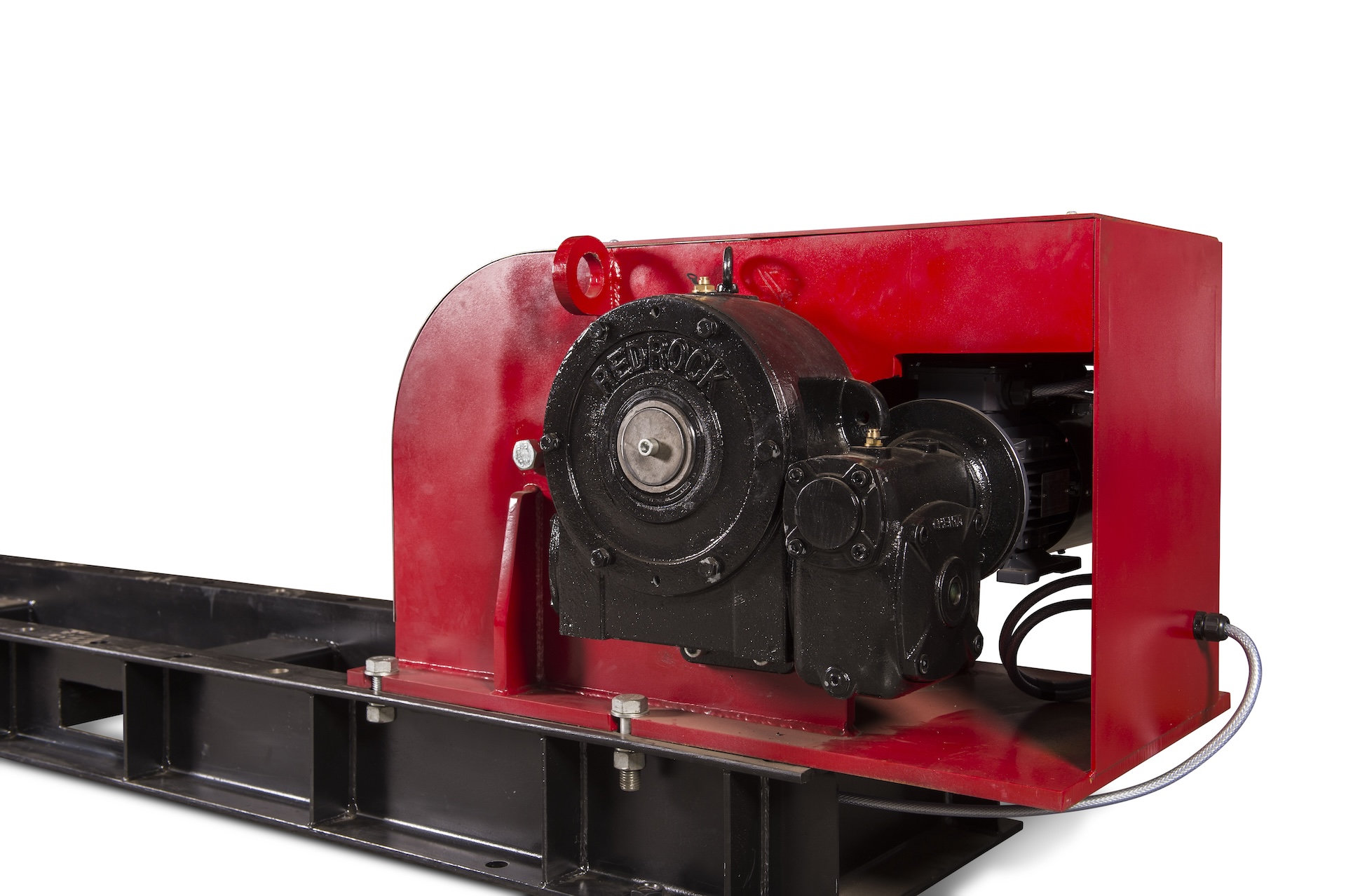

Redrock verhuurt en verhuurt lasrotators op lange of korte termijn. Wij hebben zowel conventionele rotators als zelfuitlijnende rotators, deze worden wereldwijd verzonden vanuit onze faciliteiten met interne expertise om u te voorzien van een oplossing op maat voor uw behoeften.

Ons assortiment rotators biedt het beste lasapparatuur in zijn klasse om de doorvoersnelheid te verhogen en de bedrijfskosten te verlagen. Lasrotators verminderen het risico op letsel aanzienlijk door de apparatuurhantering te minimaliseren door zware cilindrische voorwerpen mechanisch te verplaatsen.

Te Huur

Huur alleen wat u nodig hebt, wanneer u het nodig hebt.

De belangrijkste factoren die bepalen welk type rotator u nodig hebt, zijn de rotatiesnelheden, de diameter van de vaten die u op de rotator laadt en het gewicht.

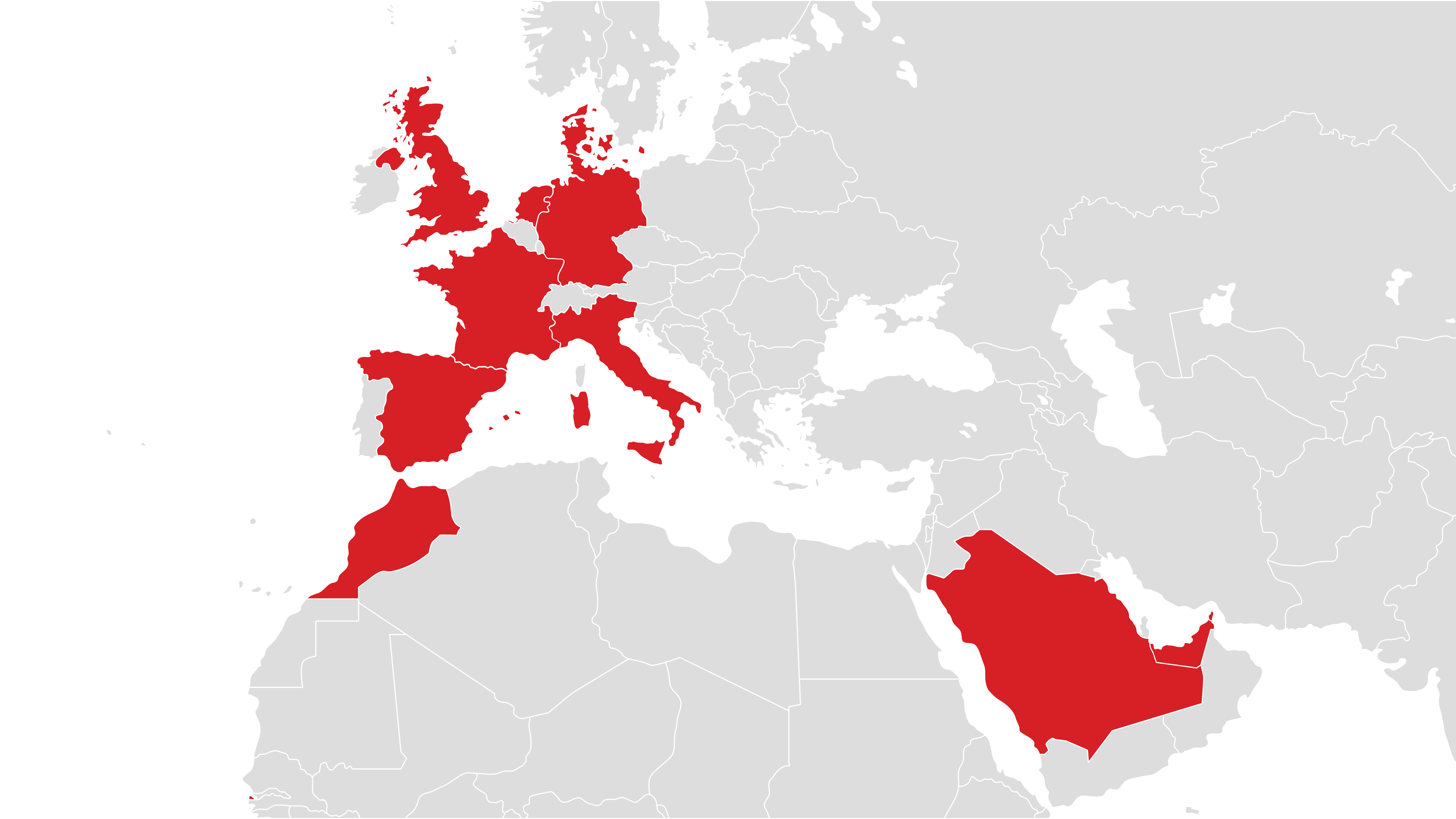

Redrock levert wereldwijd lasapparatuur van topkwaliteit – met teams van experts over de hele wereld staan we klaar om bedrijven te helpen de juiste oplossing voor hun volgende klus te vinden.

Wij bieden kosteneffectieve oplossingen en flexibele huurtermijnen, of u nu op lange of korte termijn wilt huren.

Al onze huurmaterialen worden volledig onderhouden – als u bij Redrock huurt, hoeft u geen reserveonderdelen mee te nemen, geen reparatiekosten te maken en hoeft u zich geen zorgen te maken over het onderhoud. U kunt er zeker van zijn dat alles wordt geregeld door onze getrainde technici.

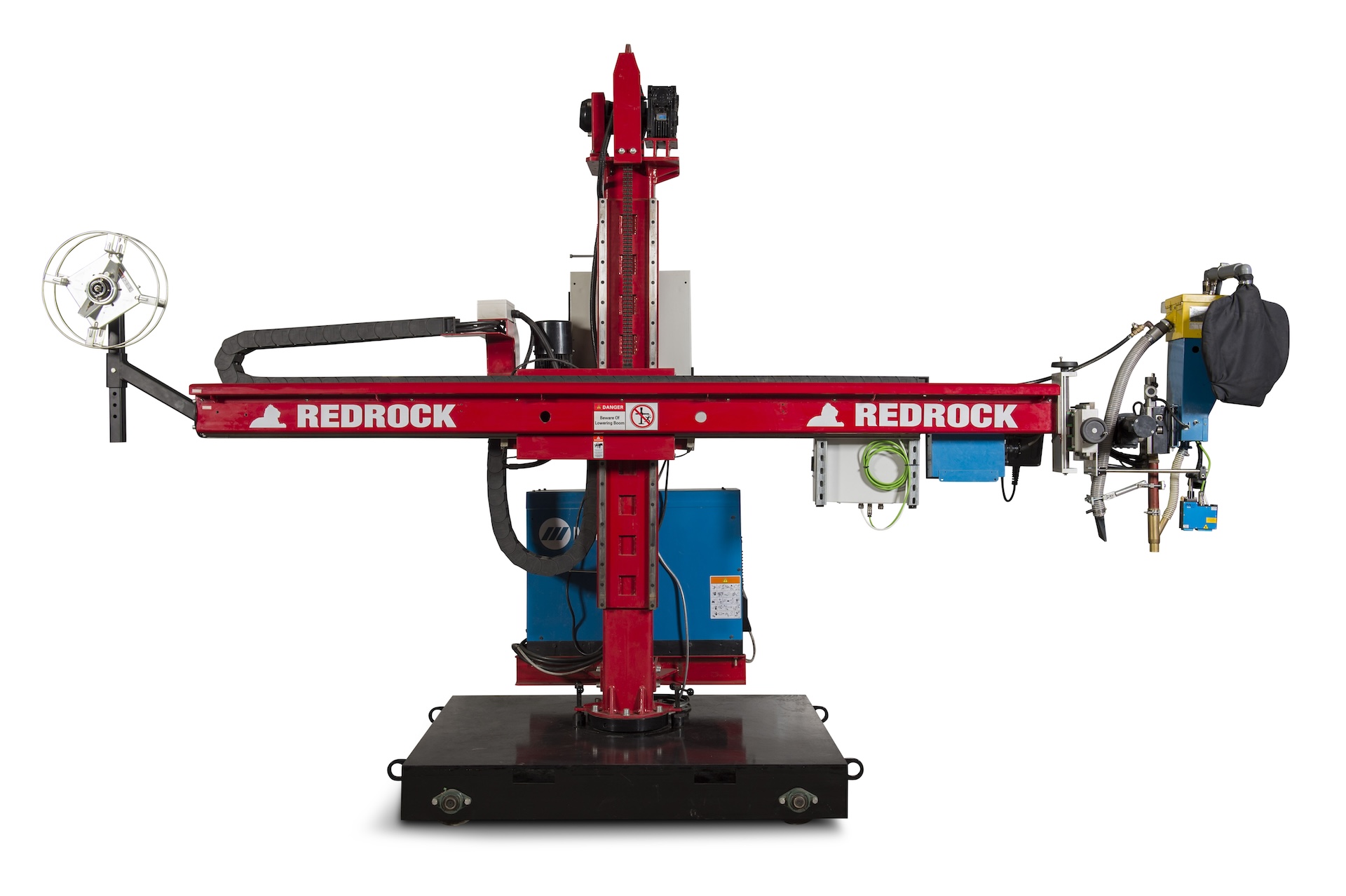

Redrock is uniek in staat om de druk van de lasindustrie te begrijpen. Wij leveren de beste kwaliteit laspositioneerders om onze klanten te helpen hun doorvoersnelheid te verhogen en zo een competitief voordeel te behalen.

Onze lasdraaitafels zijn gebouwd volgens een zwaar precisieontwerp en zijn geschikt voor diverse toepassingen, van montage- en assemblagevereisten tot geïntegreerde lassen- en overlaptoepassingen.

Redrock heeft een enorme voorraad lasmanipulatoren die geschikt zijn voor elke lastoepassing en die zorgen voor een veilige en efficiënte lasprocedure die geschikt is voor meerdere sectoren.

Praat met ons team over een oplossing op maat voor uw lasautomatisering.

Dankzij ons groeiende wereldwijde bereik kunnen wij een reeks lasapparatuuroplossingen bieden vanuit onze diverse internationale faciliteiten met wereldwijde verzending.